Principle of adhesive-free electrostatic adsorption film technology and its application in electronic device screen protection

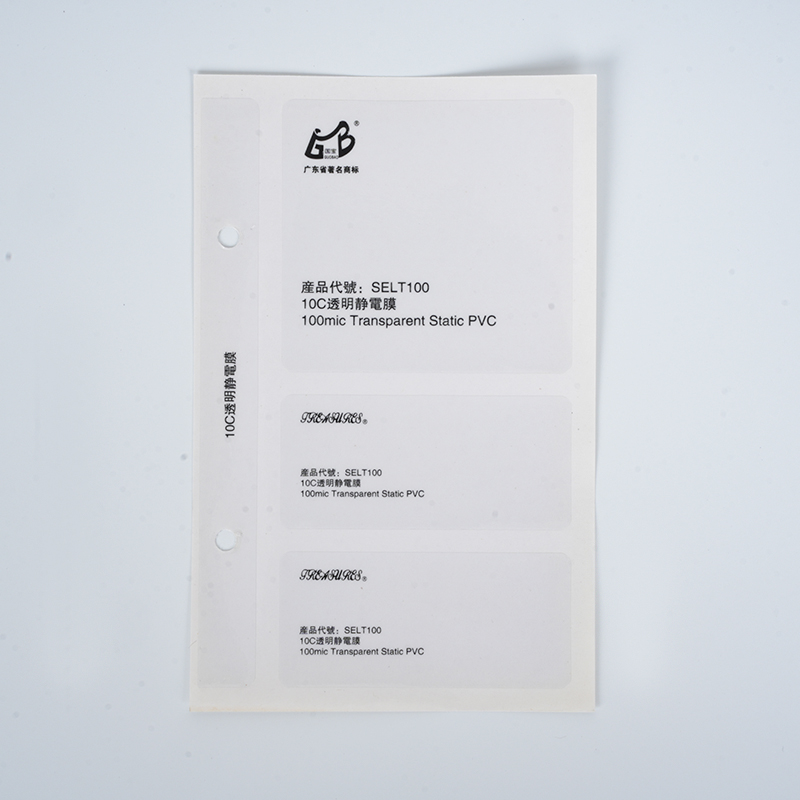

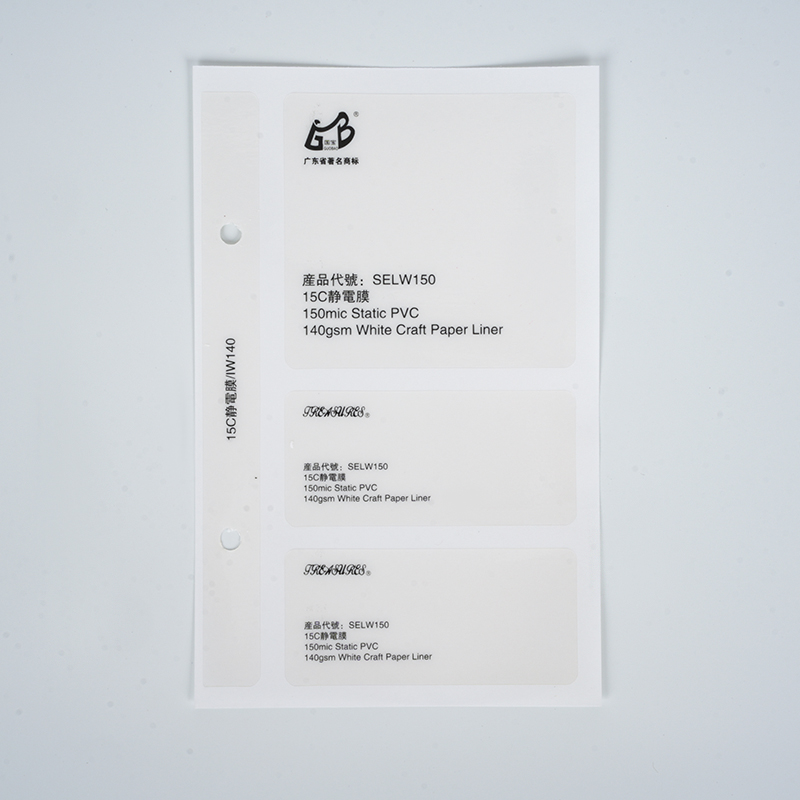

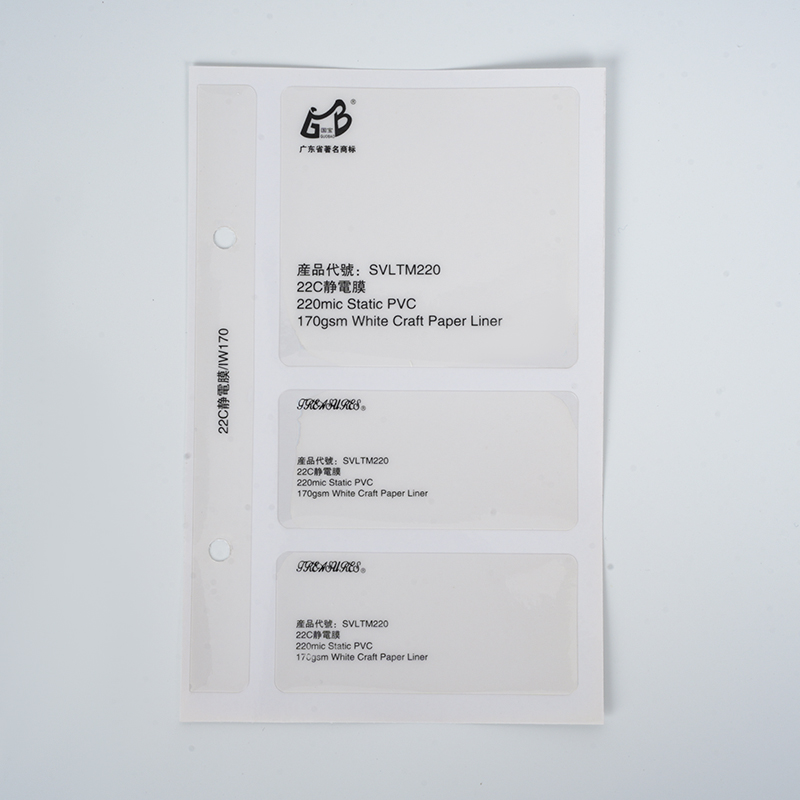

Adhesive-Free Electrostatic Film is a functional film that relies on electrostatic adsorption to achieve adhesion. It can be tightly attached to smooth surfaces (such as glass, plastic, metal, etc.) without traditional glue. Its core principles include:

Electrostatic adsorption effect: The surface of the film is specially treated with static charge, and it is adsorbed on the surface of the object through intermolecular forces (such as van der Waals force) to achieve glue-free adhesion.

Microstructure optimization: Some products use micron-level surface textures to enhance adsorption stability and exhaust properties to avoid bubble generation.

Environmentally friendly and reusable: The glue-free design makes it easy to peel off and repeatedly stick without residual glue stains, which is in line with the trend of green materials.

Application in electronic device screen protection

In the screen protection of electronic devices such as smartphones, tablets, and smart watches, glue-free electrostatic film has significant advantages:

High light transmittance: It does not affect the screen display effect and is clearer than traditional adhesive films.

No residual damage: Avoid the residue or corrosion of screen coating (such as the oleophobic layer of OLED screen) after the aging of traditional glue.

Easy to fit and replace: Users can install it by themselves to reduce waste caused by crooked or bubbles.

Dustproof and scratch-resistant: Some products are superimposed with nano-coating to improve scratch resistance and oleophobic performance.

As a pioneer in the field of self-adhesive materials in China, Baozhongbao Company has always focused on the research and development and production of functional film materials since its establishment in 1993. With the advantages of "manufacturing + R&D + service", the company continues to innovate in the field of non-adhesive electrostatic film:

Technology accumulation: Relying on nearly 30 years of experience in self-adhesive materials, we have developed electrostatic film products with high adsorption and high durability.

Market application: Provide customized solutions for global electronic equipment manufacturers and screen protector brands, and the products are widely used in consumer electronics, medical equipment and other fields.

Environmental protection concept: Non-adhesive electrostatic film complies with international environmental protection standards such as EU RoHS, helping customers achieve sustainable development goals.

+86-18018686956

+86-18018686956

Language

Language  русский

русский Español

Español عربى

عربى Tiếng Việt

Tiếng Việt